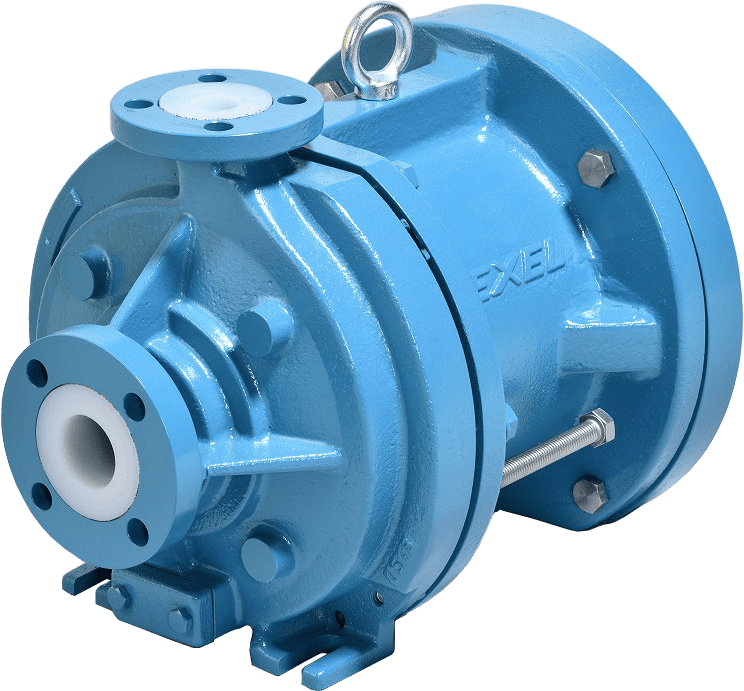

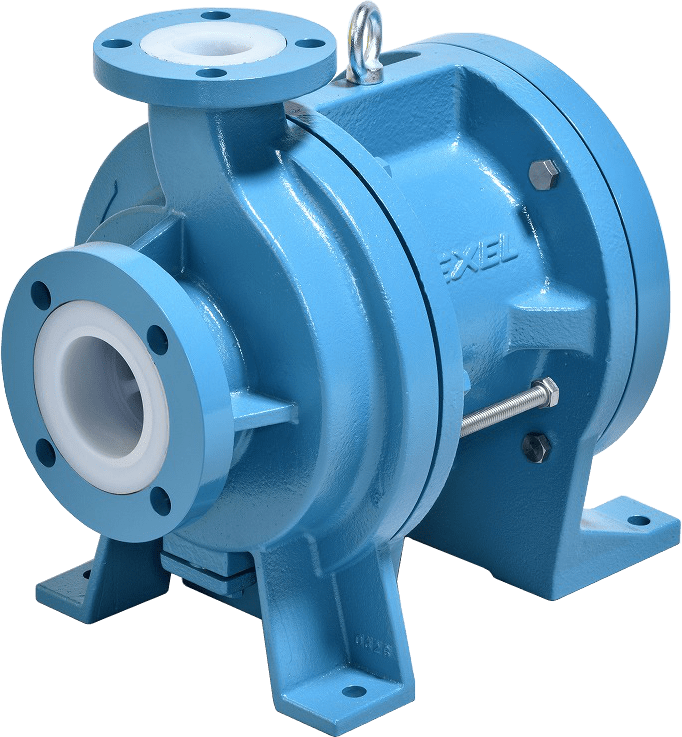

Industrial Magnetic Drive Pumps

Magnetic Drive Pumps

Texel-Seikow manufactures high-performance magnetic drive pumps for chemical processing and corrosive applications. Crafted with fluor resin materials and seal-less technology, our pumps deliver unmatched durability and leak prevention.

Trusted by professionals worldwide, Texel is your reliable source for corrosion-resistant pumps that keep operations running smoothly. Discover efficient fluid handling that meets your most challenging process demands.

Why Texel Is a Leading Magnetic Drive Pump Manufacturer

Texel-Seikow has been manufacturing magnetic drive pumps in Houston, Texas, since 1991. We build our pumps to prioritize chemical resistance using fluor resin materials and seal-less construction to eliminate leakage.

Our team manages every stage under one roof, from design and production to testing and assembly. This ensures consistent quality and short lead times with every purchase.

Chemical manufacturers across the US turn to us for corrosion-resistant pumps that meet their exact chemical handling and durability requirements.

Corrosion-Resistant Pumps Built for Harsh Environments

Texel-Seikow manufactures magnetic drive pumps that perform reliably in chemically aggressive, high-risk applications. Our corrosion-resistant pumps use high-purity fluor resin materials and seal-less technology to meet the demands of harsh process conditions without failure or leakage.

Aggressive Chemical Compatibility

Texel’s magnetic drive pumps handle many corrosive and hazardous chemicals, including acids, alkalis, and solvents commonly used in chemical manufacturing.

When exposed to aggressive fluids under continuous operation, each pump maintains structural integrity and flow performance.

Our flour resin-resistant pumps provide long-term chemical resistance without deterioration or material swelling. This allows operators to avoid contamination, shutdowns, or costly damage to surrounding equipment.

The Benefits of Magnetic Drive Technology

Seal-less magnetic drive pumps eliminate the risk of shaft seal failure and fluid leakage. This reduces the need for ongoing maintenance and enhances operational safety in environments where leaks can cause equipment damage or health hazards.

Magnetic drive systems use a synchronous coupling between the motor and impeller to transfer energy without direct contact. This design isolates process fluids from the motor components and supports continuous use in hazardous chemical services.

Fluor Resin Construction for Maximum Chemical Resistance

Texel-Seikow crafts pump components using fluor resin materials such as ETFE and PFA, which provide excellent resistance to acids, caustics, and organic solvents.

These particular materials resist degradation under elevated temperatures and prolonged chemical exposure.

Fluor resin construction also prevents corrosion-related failures, reduces downtime, and extends pump life. Our corrosion-resistant pumps support applications where metal components fail, or high-purity fluid handling is necessary.

Inside Our Industrial Drive Pump Manufacturing Process

Texel Seikow manufactures industrial magnetic drive pumps at our Houston facility with complete in-house control.

Here’s a quick look at how our manufacturing process works:

- Engineering and Material Selection: Our team selects fluor resin materials based on chemical compatibility requirements. We engineer pump configurations to match each application’s pressure, flow rate, and fluid characteristics.

- Component Fabrication and Machining: We machine internal and external pump parts to exact tolerances for your operations.

- Assembly and Magnetic Coupling Installation: The team assembles the pumps carefully to maintain internal alignment and sealing surfaces.

- Testing and Final Inspection: We test each magnetic drive pump for flow rate, power consumption, and leak resistance under controlled conditions. The final inspection confirms that all specifications match customer and internal standards.

Request a Quote for Your Magnetic Drive Pump Needs

FAQs: Magnetic Drive Pumps

Find out more about magnetic drive pumps through our most frequently asked questions.

What industries benefit most from Texel magnetic drive pumps?

Our magnetic drive pumps are used in chemical processing, wastewater treatment, semiconductor manufacturing, plating facilities, and pharmaceutical industries. However, Texel’s seal-less pump technology can benefit any application requiring chemical resistance and process purity.

Can magnetic drive pumps handle solids or slurries?

Magnetic drive pumps are ideal for clean, corrosive fluids. Applications involving suspended solids or abrasive slurries may require special configurations.

Do you offer replacement parts or repair services?

Yes! Texel stocks magnetic drive pump replacement parts at our Houston facility. We provide fast turnaround on component orders and offer technical support for inspection, repair, and maintenance to minimize downtime.